Importance of Industrial Painting For Your Silos & Storage Tanks

Do you want to protect your assets, improve company morale, and strengthen your brand? There is one thing you can do to check all these boxes for your facility.

Paint your silos or storage tanks.

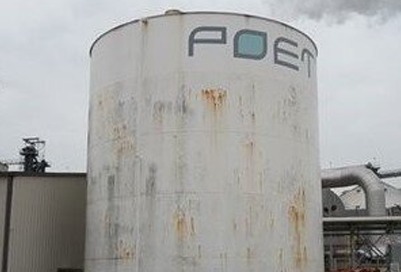

Look out your window. How do your storage tanks look? Food manufacturing, pharmaceuticals, and petroleum are a few industries where it is common to have exterior storage bins, tanks, or silos. In fact, it may be vital to your production. Here’s why painting them could be the best investment you can make.

PROTECT YOUR ASSETS

Corrosion is the biggest threat to silos and can impact the exterior as well as the interior. This poses the risk of contamination when you consider the storage of food. Industrial coating is the single greatest protection you can provide your silos and storage tanks regardless of the material they are composed of.

Think about the exposure to harsh elements over extended periods and the unavoidable freeze-thaw cycle in some areas. It just magnifies the importance of properly maintaining your exterior storage and equipment.

MAKE AN IMPRESSION

Have you ever heard of the primacy effect? This is the idea that when people experience things in a sequence, the first thing is what they remember more. This is the reason why first impressions are so important. The initial encounter greatly influences someone’s views or ideas and it can be hard to change.

The way the outside of your facility looks when someone drives by impacts their view of your company and your product. Therefore, the appearance of your exterior equipment is crucial to your company’s image and brand.

Improving the aesthetics of the facility exterior may also improve the morale of the company. It can elicit feelings of pride for employees and even the community.

PREPARATION FOR PAINTING

The first step in the painting process is industrial cleaning. This could be a detailed power wash or abrasive blasting (also referred to as sandblasting). This step is absolutely necessary to ensure the adhesion and durability of your new coating.

Any loose coating needs to be removed. This process will look different for each facility. A professional painting contractor will have the knowledge and options to best fit your project needs. Keep in mind this may reveal additional concerns which may be the root cause of the coating failure. Any deficiencies in the soundness of your storage container need to be remedied prior to paint to prolong their life.

One such problem could be extensive rust. Covering rust without properly preparing is just putting a band-aid on an infection. It will continue to spread and further damage your structure.

PAINT AND APPLICATION

Once you have adequately prepared the surfaces, be sure to select the right paint products for your application. The first coat should always be a primer. On steel that might require a rust-inhibiting primer to prevent corrosion. A masonry sealer may be necessary on concrete.

Working top to bottom on all projects provides the most efficient process, but selecting the right paint makes the difference in your final result and the longevity of your coating. Again, each project is unique so be sure you are working with an industrial painting professional, like Blast It Clean.

Hiring a reputable company to perform your storage container restoration results in getting the job done efficiently with little downtime and minimal service interruptions. Blast It Clean is happy to accommodate “off” hours to reduce disruption to your facility's production. We also have the ability to receive and complete the work on non-fixed-base projects at our worksite in Kansas City, Missouri. This offers additional flexibility for clients with medium-to-small-sized projects.

For an evaluation of your silos or storage tanks, call Blast It Clean (877) 379-4233.