SPONGE-JET BLASTING WITH BLAST IT CLEAN

Sponge blasting is dry, clean, and non-invasive, creating low dust to dustless blasting environment. It is applicable on multiple surfaces and is friendly to sensitive assets. Coating created after sponge blasting also has a more durable life span. You really are in tune with the project you have going on when you are seeking sponge-jet blasting. We are one out of three companies that does sponge-jet blasting services in the midwest.

ADVANTAGES OF SPONGE-JET BLASTING

WHY SPONGE-JET BLASTING?

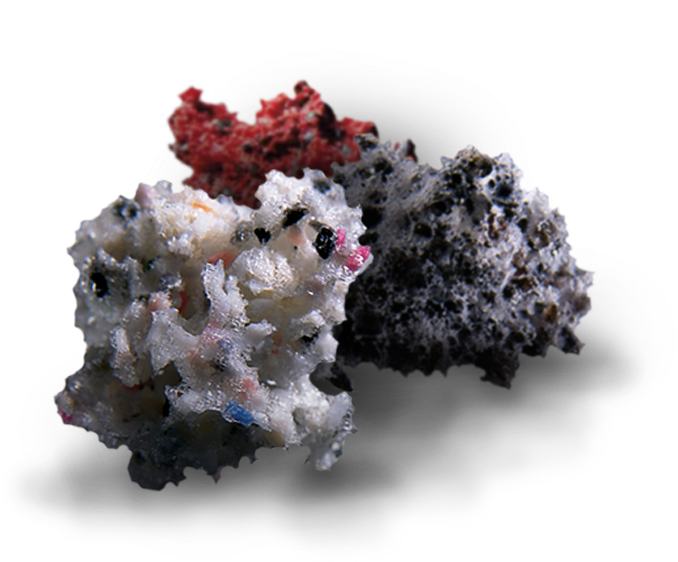

Sponge blasting could reduce up to 96% of waste and 98% of hazardous dust. It is both friendly to the blaster and the blasting environment. Over 25 different types of sponge particles are available. each with different abrasive measurements that are infused into the sponge.

The sponge media is cost-effective, healthy, and environmentally responsible. It is an effective media in mold remediation, nuclear remediation and is suitable for blasting valuable and sensitive assets such as military and marine equipment.

FEATURES

- Low dust blasting

- Non-invasive on the surface

- Flexible applications

- Reduces media waste

- Environmentally friendly

- Reduced recoil - personnel safe

Sponge-Jet blasting has been talked about as being one of the best choices in environmentally friendly methods of low dust to dustless blasting. With a high yield of waste reduction and a reduction in hazardous waste, these reasons alone make this a sustainable option for your blasting needs.

COMMON INDUSTRY APPLICATIONS

HOW DOES SPONGE-JET BLASTING WORK?

The process begins with Pressurized feed units, which store and propel the sponge particle abrasives to the surface that needs to be cleaned or prepared. These units are equipped with mechanisms to maintain consistent pressure and feed rates, ensuring that the blasting process is both efficient and controlled.

A centralized control panel plays a crucial role in Sponge-Jet blasting. It allows operators to adjust the blast pressure and media feed rate according to the job's specific requirements. This precise control enables the operator to target the surface with accuracy, making it suitable for various applications, from delicate cleaning to heavy-duty surface preparation.

When the sponge particles strike the surface, they undergo a unique transformation. Upon impact, these particles flatten, revealing the abrasive infusions within. This mechanism allows for effective cleaning or surface preparation by removing contaminants, coatings, or rust. The sponge structure of the particles is essential in ensuring a controlled and efficient impact.

As the sponge particles hit the surface, they create a vacuum effect during rebound. This vacuum effect, generated by the expansion of sponge cells, efficiently sucks up the debris and contaminants from the surface. This is a significant advantage as it prevents hazardous particles from becoming airborne, making the process safer for both workers and the environment.

Unlike traditional abrasive blasting methods that often result in high-energy rebound, Sponge-Jet blasting has a low-energy rebound. This means that the abrasive particles do not bounce off the surface with great force, minimizing the risk of damage to nearby structures or surfaces and making cleanup much easier.

Sponge-Jet blasting is highly efficient in terms of media usage. After the blasting process, a recycler is employed to clean and classify the used sponge particles. This step involves separating the media from oversized debris and fine waste. Remarkably, approximately 95% of the sponge media can be recycled at this stage. This recycling capability is a significant environmental benefit, reducing waste and lowering the overall cost of the blasting process.

One of the standout features of Sponge-Jet blasting is its eco-friendliness. The ability to recycle a large portion of the abrasive media, combined with the containment of hazardous particles during blasting, makes it a sustainable choice in surface preparation. It helps reduce waste generation, minimize environmental impact, and comply with environmental regulations.

Sponge-Jet blasting is a cutting-edge method of surface preparation that combines precision, efficiency, and environmental responsibility. Its controlled blasting process, low energy rebound, and high recycling rate make it a compelling choice for industries and applications that demand both effective surface preparation and environmental stewardship.

BLAST IT CLEAN - SPONGE-JET BLASTING SERVICES FOR RESTORATION

Rehabilitation is a sensitive process. Older architecture is fragile or already cracked and deteriorating. Whatever the case may be, you need a method that is light on abrasive but can reach into detailed moldings, cracks, and crevasses. Chemicals can be harsh and difficult to dispose of and water may not be containable, especially with an indoor job. Sponge-jet may make the most sense with your needs and specifications.

Using sponge-jet for other restoration projects such as removal of soot, smoke, and graffiti is also an effective way to retain the integrity of your structure.