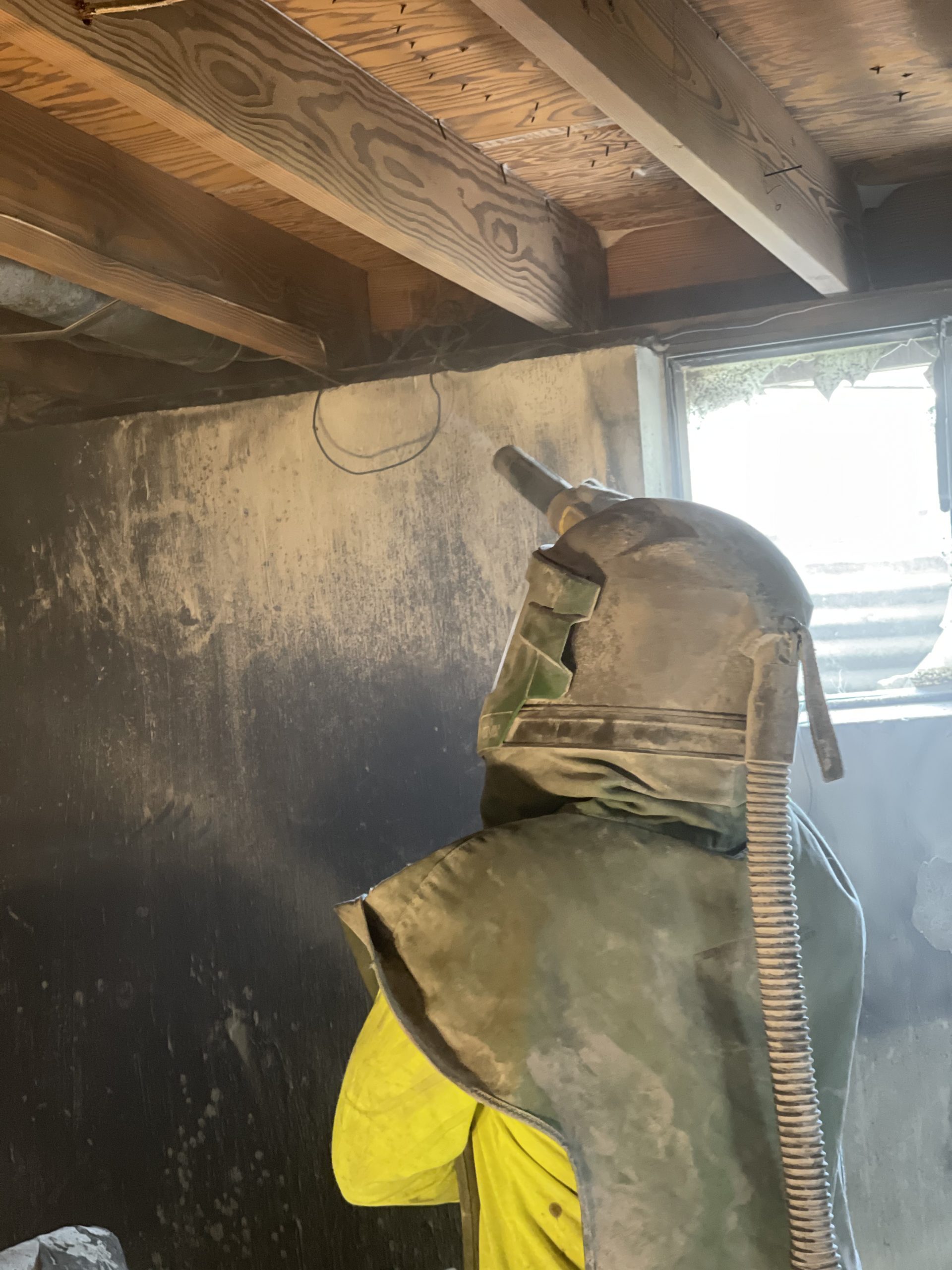

SODA CLEANING WITH BLAST IT CLEAN

WHAT IS BAKING SODA BLASTING?

A newcomer to the world of abrasive blasting, baking soda blasting has established its efficiency in multiple fields such as fire damage restoration and historic restoration.

Baking soda, scientifically known as sodium bicarbonate is one of the gentlest mediums in the blasting world with a relative MOHS hardness of 2.5 compared to other media, which can contain a hardness up to 9. As a result, soda blasting is applicable on more delicate surfaces such as canvas, damaged or untreated wood, historic brick, fabric, plastic, and sometimes glass when properly applied. Baking soda is an environmental-friendly solution as it is biodegradable, non-toxic, and water-soluble.

Blast It Clean utilizes this media often, especially in fire restoration, as we have found it to be the most efficient in labor costs and all-purpose for a soft abrasive and a deodorizer/neutralizer.

HOW DOES THE PROCESS WORK?

When baking soda is blasted out of the blasting hose, it is released with a strong impact on the targeted surface. This impact provides energy to effectively remove stains, paint, or debris from the surface.

Because baking soda is such a soft medium, it is able to provide enough energy for paint stripping and stain removal, without “burning into” the surface as long as the application is appropriate.

USES OF SODA BLASTING IN DISASTER RESTORATION

The ability to clean and deodorize makes soda particularly valuable in disaster restoration. It is able to remove soot, char, and other residues from a fire quickly and thoroughly. Besides the physical damage, fire leaves behind an odor from smoke and burning material. The particles and odors settle deep into surfaces and can be tough to remediate. It gets in those same cracks neutralizing the smell.

Soda blasting can do the same thing to mold. While microscopic mold is naturally present everywhere, the invasion of water to your property can trigger mold growth as quickly as a few days. Mold remediation eliminates the colonies that cause a strong, musty odor. It can kill mold spores and remove mold growth in addition to absorbing the odor.

COMMON BAKING SODA USES BY INDUSTRY

FOOD PROCESSING & MANUFACTURING

Since baking soda is considered FDA food-grade approved, it's perfect for the food and beverage industry.

INDUSTRIAL MANUFACTURING

We understand that removal of corrosive materials or residue per square foot can get time-consuming and costly for industrial manufacturers. Soda blasting can be an efficient and effective method of removing and deodorizing your industrial facility.

HISTORIC RESTORATION

Soda is a less abrasive media, making it less aggressive against fragile structures like historic brick, sculptures, and fine metals.

REMEDIATION & RESTORATION

Our most common form of soda blasting application is fire remediation and restoration. We perform restoration services on any interior or exterior surfaces from residential up to the government and industrial facilities. It is a perfect abrasive for delicate structural materials such as wood that has been stained from soot and char. It not only removes fire residue but deodorizes the areas as well.

COMMON BAKING SODA APPLICATIONS

ADVANTAGES OF BAKING SODA

DEEP CLEANING

Able to penetrate multiple layers of paint.

ENVIRONMENTALLY RESPONSIBLE

It dissipates and settles quickly, doesn't leave behind any residue, and is non-toxic to humans and other wildlife making it USDA approved.

VERSATILE

Applicable on various surfaces.

EXTRA FINE ABRASIVE

Low abrasive rate on the targeted surface.

NO CHEMICAL FRICTION

Sodium bicarbonate is not like most other chemical or abrasive cleaners. It has zero heat generation, which means it won't burn or leave lasting heat damage or markings.

WATER-SOLUBLE

Water-soluble with a PH of 8.2.